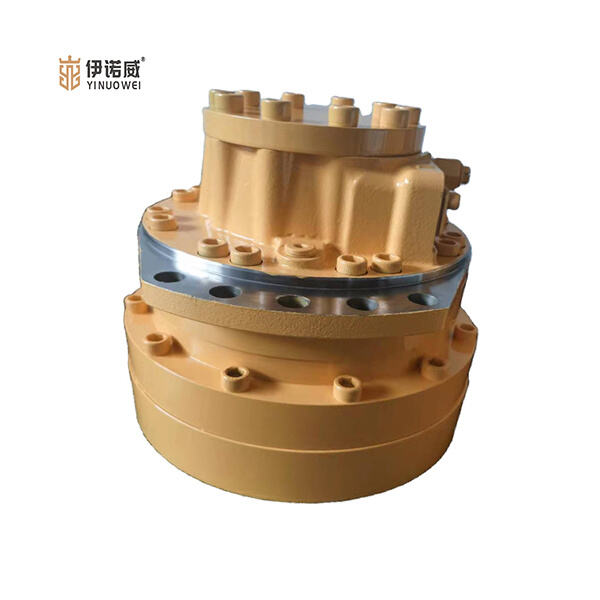

If you’ve been to a construction site or a factory, you may have noticed big machines that help lift and move tons of stuff around. They are strong machines and are used in a wide variety of jobs. They utilize something known as hydraulics. Hydraulics is a form of technology that employs fluids to perform work in machines. This hydraulic system consists of several key components, one of which is the omm 32 hydraulic motor.

Hydraulic radial piston pump: a specialized liquid moving pump. It controls the parts of it, which are little parts called pistons, like tiny tubes, to make the fluid go and make the pressure. It helps machine to run in better way with less effort as its significant importance. These pumps are everywhere from construction machines to car brake systems and factory machinery.

Hydraulic Radial Piston: Radial pistons are intended to move within a circular path. This rotary motion is crucial, as it enables the pistons to expanse out against the interior of the pump. All these comes together to help the pump function more efficiently and more reliably over time.

Cylinder Blocks: These are other significant members of these particular pumps. These blocks can rotate around a central part called the drive shaft. Every cylinder block contains multiple pistons, which shift in and out as the block rotates. The motion creates pressure, forcing the liquid out of the pump, enabling it to perform its job.

Valve Plates: The valve plates are another key component to hydraulic radial piston pumps. They control the liquid flow within the pump. These pumps have valve plates specially designed for high pressures and high temperatures, so they are very strong and durable.

Refilling the Fluid: The hydraulic fluid within the pump can deteriorate as time goes on. This causes performance losses to severe damage of the pump. This needs to be followed by regular replacement of the fluid to ensure that the pump is operating under optimum conditions.

2) Pressure Check: You should always make sure there is not too much pressure created by the pump. Monitoring the pressure levels can also alert you if something is off. Its primary function is to monitor the pressure and notify you if there is a problem with an unexpected drop in pressure because a pump might have an issue.